Recent Projects

Expert Emission Solutions for Our Power and Industrial Clients

Here are just a few projects we've delivered emission expertise on:

Project Highlight // Long Beach, CA

Large-Scale SCR Catalyst Retrofit

SCR Solutions worked for 2+ years to develop this complicated LM6000 SCR retrofit project in Long Beach, CA. Work included inspections, CFD modeling, detailed engineering to fabricate and install new perforated plate, catalyst frames, supports, and AIG. SCR Solutions also provided onsite field supervision of the retrofit work. After the work was completed, we also did a performance test. Their stack NOx, CO and ammonia slip were all dramatically reduced from their previous operations. Overall this project was a huge success

Please contact SCR Solutions for a detailed review

Project Highlight // Ohio

HRSG/SCR Testing

SCR Solutions provided detailed NOx, temperature and ammonia slip measurements 1x1 combined cycle plant in Ohio. The plant was experiencing high ammonia slip and poor NOx control when duct firing, thereby limiting operation. SCR Solutions utilized our Top Traverse Method to obtain a detailed map of the NOx, O2, ammonia slip distribution at the SCR. The results indicated high ammonia slip specifically in line with the damaged upstream HRSG baffles. High temperature flue gas was getting to portions of the SCR catalyst that limited its overall performance. After the SCR Solutions’ recommended repairs were made to the HRSG baffles, the unit was able to comfortably operate with duct firing with no limitations on operation.

More details can be found in a recent article published in the Combined Cycle Journal

New York

SCR traverse testing & AIG tuning

SCR traverse testing and AIG tuning performed on this 400 MW cogeneration plant in New York City. Improvements were made to their distribution and limited local high ammonia slip regions. SCR Solutions is now performing CFD modeling to further optimize their ammonia distribution.

California

CO catalyst retrofits

SCR Solutions spent several months supporting CO catalyst retrofits at these 2 California LM6000 and LMS100 simple cycle plants. Both projects went very well and are easily meeting their CO emission requirements.

Illinois

Detailed traverse testing

Detailed traverse testing was performed on this newly commissioned 2x1 1000 MW combined cycle plant in Illinois.

Mexico

HRSG/SCR Testing

SCR Solutions provided detailed NOx, temperature and ammonia slip measurements on a 2x1 combined cycle plant in Mexico. SCR Solutions utilized our Top Traverse Method to obtain a detailed map of the SCR performance before and after SCR catalyst cleaning and subsequent repairs.

Texas

SCR AIG Tuning & Inspection

SCR Solutions provided detailed NOx measurements and AIG tuning for a 2x1 combined cycle plant in Texas. The plant was experiencing high ammonia slip and poor NOx control under certain operating conditions since startup in 2014. SCR Solutions utilized our Top Traverse Method to obtain a detailed map of the NOx, O2 and ammonia slip distribution at the SCR. The results indicated some suspicious areas where gas bypass might exist.

A follow up inspection was performed during a scheduled outage and areas of significant gas bypass regions. SCR Solutions is working with the plant to repair the problems and solve the performance problems.

Ohio

HRSG/SCR Testing

SCR Solutions provided detailed NOx, temperature and ammonia slip measurements 1875MW combined cycle plant in Ohio. SCR Solutions utilized our Top Traverse Method to obtain a detailed map of the NOx, O2, ammonia slip distribution at the SCR on all three of their units. The plant used this data to confirm SCR performance and make sure they have a great baseline set for future checks.

Ohio

HRSG Duct Burner Testing

SCR Solutions provided detailed testing at this 1200 MW combined cycle plant in eastern Ohio. Duct burner inlet and outlet traverse testing to identify some performance issues they are having. The data is to be used by SCR Solutions, the plant and OEM to come up with some fixes to the flow distribution entering the duct burners to improve performance.

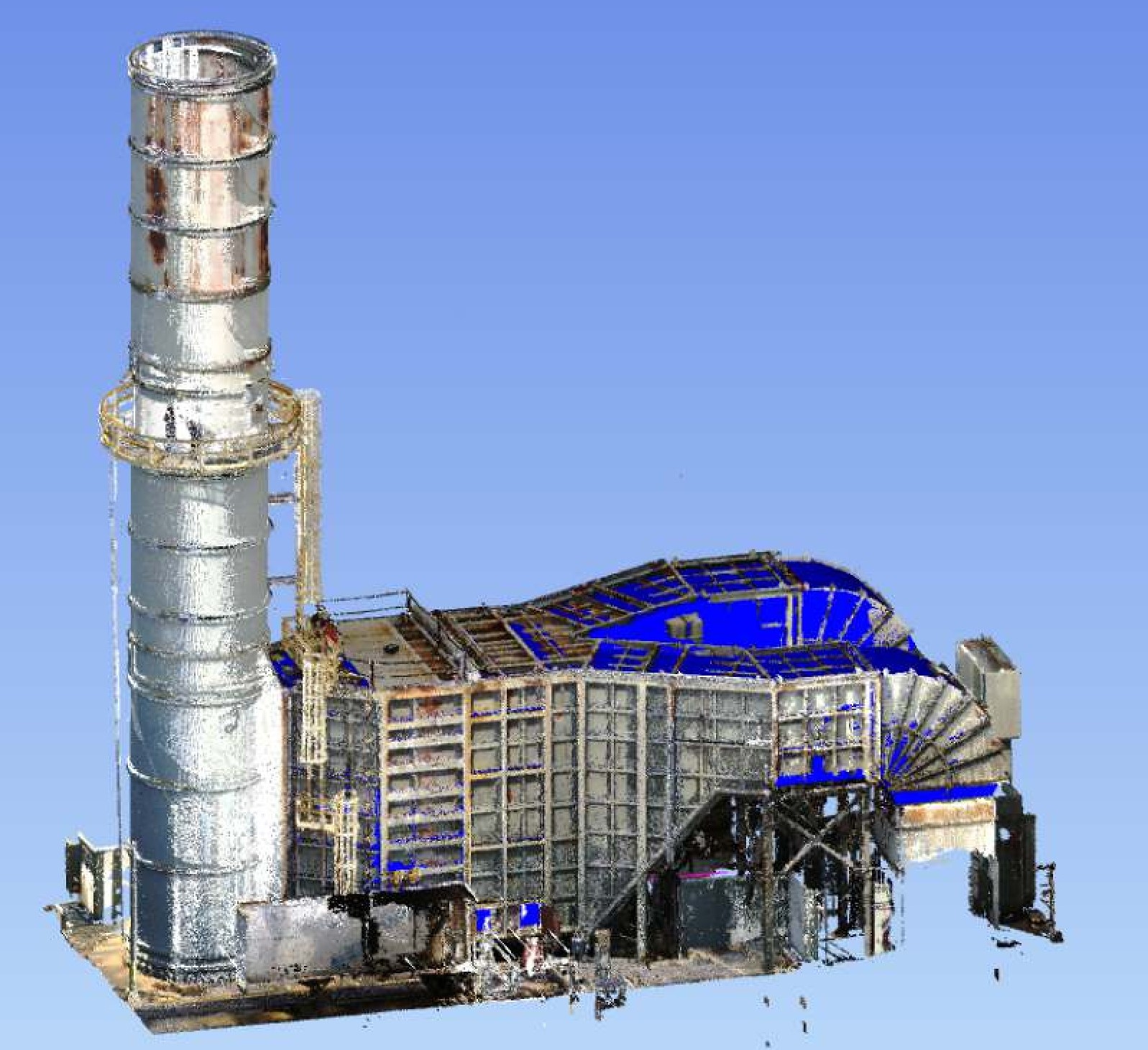

New Jersey

Laser Scan of HRSG Casing

A 540MW combined cycle plant was experiencing elevated CO emissions, and SCR Solutions was brought in to investigate. During an internal inspection, a significant gap was discovered between the internal liner and the CO catalyst frame, allowing gas to bypass the catalyst, resulting in high CO emissions.

The root cause appeared to be deformation of the Heat Recovery Steam Generator (HRSG) casing, but the extent of the deformation was unclear. To gain a more precise understanding, SCR Solutions conducted a laser scan of the entire CO catalyst HRSG section. By overlaying the scan with the original design drawings, it was revealed that the HRSG casing had bowed out by nearly 5 inches—a substantial discovery.

This insight was instrumental in developing a remediation plan to straighten and reinforce the casing. The project demonstrated the immense value of laser scanning technology, not only in diagnosing structural issues but also in improving emissions control.

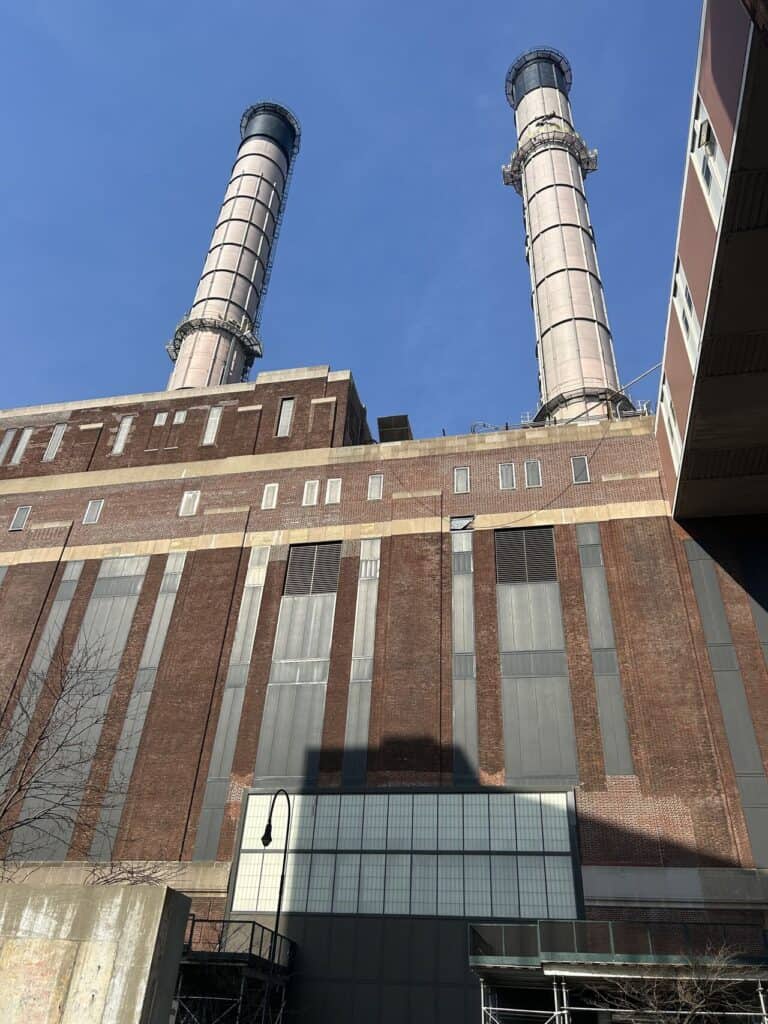

New York

Laser Scan of SCR

SCR Solutions is working with a 50MW peaking plant to address issues with NOx, CO, and ammonia slip emissions. A key challenge was the lack of OEM drawings or as-built documentation for the internal components from the turbine exhaust to the exit of the SCR catalyst.

To overcome this, SCR Solutions conducted a comprehensive laser scan, collecting detailed internal and external measurements. A total of 44 individual scans were combined to create a precise 3D AutoCAD model of the unit.

This model will now enable the team to perform computational fluid dynamics (CFD) analysis to better understand and resolve flow, temperature, and ammonia distribution issues. By leveraging this cutting-edge technology, SCR Solutions is helping the plant achieve more effective emissions control.